Apron feeder

Apron feeder manufacturer Chain plate feeder for sale - China

Henan Henanmining Machinery Co., Ltd, China Apron feeder manufacturer. Apron feeder are generally divided into three types: heavy, medium and light.

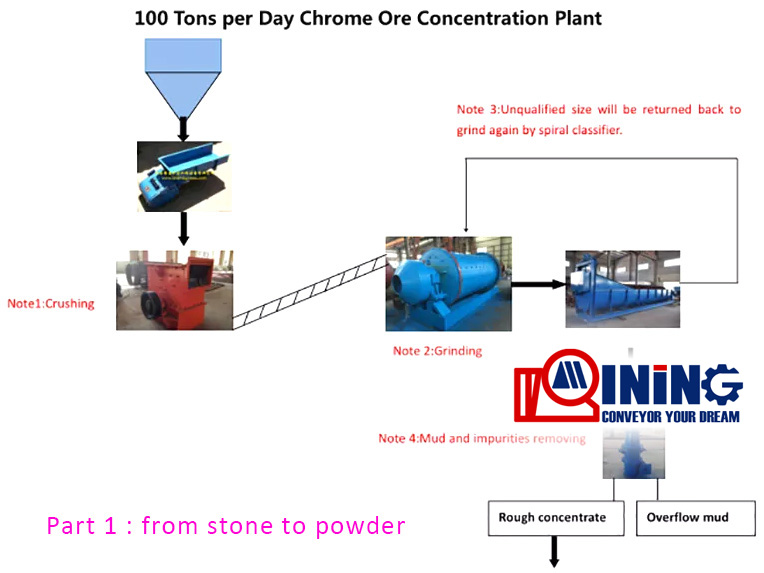

Apron feeder is a kind of conveying equipment that can convey materials of different particle sizes and different bulk densities to various receiving devices.

The machine is mainly used for continuous and uniform feeding from the storage bin to the crusher, conveyor or other machinery , It can also be used for short-distance transportation of bulky and dense materials, widely used in mining, metallurgy, building materials, chemical, coal and other industries.

Heavy apron feeder

As a silo to feed the primary crusher continuously and uniformly, the heavy-duty apron feeder can also be used for short-distance transportation of materials with larger particle size and specific gravity, larger particle size, and higher temperature. The heavy-duty apron feeder can be installed horizontally or obliquely, with a large inclination angle of 20°

Medium apron feeder

Medium Apron feeder Intermittent feeding machinery, is suitable for short-distance conveying of bulk materials with a particle size of 400mm or less. In the mining, processing plant, chemical industry, cement, building materials and other departments, it is widely used for uniform intermittent feeding from storage silos to crushing, transportation and other machinery. It can be installed horizontally or obliquely, with a very large upward inclination angle of 20 degrees. Generally, it is suitable for materials with bulk density less than 12400kg/m3, block weight less than 500kg, and temperature below 400℃.

Light apron feeder

The light apron feeder is a continuous feeding machine, suitable for short-distance conveying of bulk materials with a feeding size of 160mm or less. In the mining, processing plant, chemical industry, cement, building materials and other departments, it is widely used for uniform and continuous feeding from storage silos to crushing and transportation machinery. It can be installed horizontally or obliquely, with an upward inclination angle of 20 degrees. Generally, it is suitable for materials with bulk density less than 1200kg/m3, block weight less than 140kg, and temperature below 350℃.

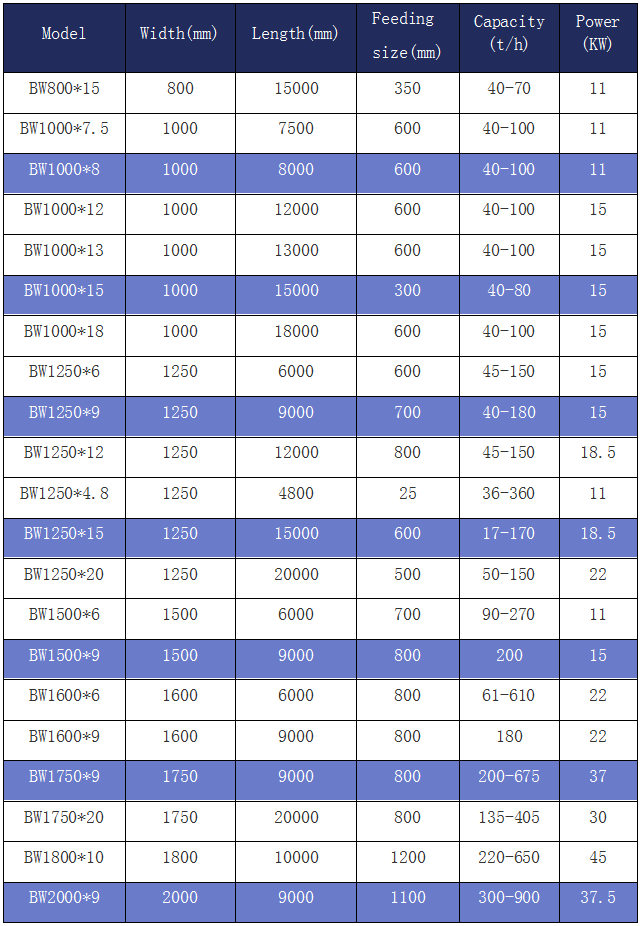

Parameter of the Apron feeder

Features of apron feeder

The towline chain of the heavy-duty apron feeder adopts the standard dry crawler chain produced by a professional manufacturer, which does not require lubrication, and has high tensile strength and is easy to install and maintain. The chain plates of the heavy-duty plate feeder are of stamping and welding structure, and the arc-shaped overlap between the chain plates prevents material leakage during work, and the chain plates are strengthened underneath, which has a large bearing capacity. The driving device of the heavy-duty apron feeder adopts a suspended single-point floating support method, and the tooth diameter is consistent without the influence of the basic accuracy, which can greatly reduce the radial installation size of the apron feeder.