Lime rotary kiln

China Lime rotary kiln, active lime production line factory

Henanmining's lime kilns are divided into horizontal lime rotary kiln and vertical lime rotary kiln

Vertical lime kiln capacity : 50 - 550 tpd

Horizontal lime rotary kiln capacity : 100 - 1200tpd

Click to learn more about the vertical lime kiln. This article mainly introduces the horizontal lime rotary kiln production line .

Main equipment of lime production line

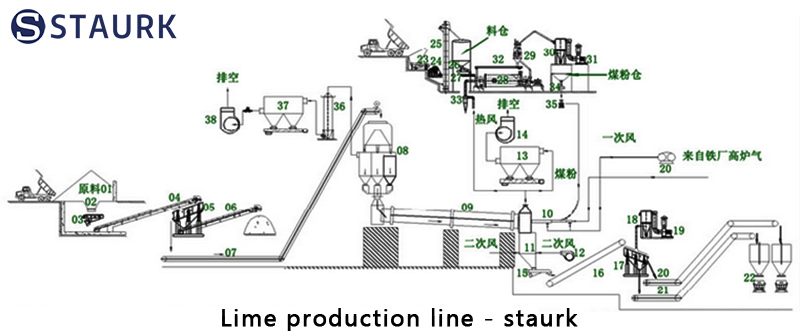

The new lime rotary kiln adopts advanced vertical preheater + rotary kiln + vertical cooler technology, adopts hydraulic thrust stopper device, and uses intelligent central control system to realize unmanned operation in the production area. It can carry out technologies such as all-gas calcination, all-coal pulverized calcination, and co-firing of gas and pulverized coal to ensure the production of high-quality lime.

1. Raw material 8. Vertical preheater 9. Rotary kiln 10. Burner 11. Vertical cooler 12 Secondary fan 13. Kiln head dust collector 20 14. Fan 18. Vibrating screen dust collector 19. Fan 23 Vibrating Feeder 24. Jaw Crusher 25. Fighter Hoist 27. Electronic Belt Scale 28. Ball Mill 29. Powder Concentrator 30. Dust Collector 31. Fan 32. Screw Conveyor 33. Dust Collector 37. Dust Collector 3. 15. 26. Electromagnetic vibrating feeder 4.6. 16. Belt conveyor 5.17. Vibrating screen 14.19.31. Fans 7.20.21.Large inclination belt conveyor

What is Active Lime

Activated lime (or soft burnt lime) is quicklime. Activated lime refers to lime that is roasted in the range of 920°C to 1200°C. The specific parameters are CaO ≥ 90%, MgO ≤ 0.7 %, activity ≥ 300ml

Learn more about the difference between active lime and ordinary lime

Raw material for lime production line

The raw materials used to produce active lime are mainly carbonate rocks, and the elemental composition is mainly CaCO3, which is what we usually call limestone. There are many types of limestone, the common ones are: granular crystalline limestone, dense limestone, porous limestone, earthy limestone, marl limestone, chalk, dolomite, shell limestone river pebbles, etc.

In the selection or use of lime raw materials, among many grades of limestone, the content of calcium oxide is often more than 54%, and the content of impurities such as silicon dioxide, sulfur, phosphorus, magnesium oxide, ferric oxide, and aluminum oxide is low. The value of limestone is used as the raw material for calcining active lime.

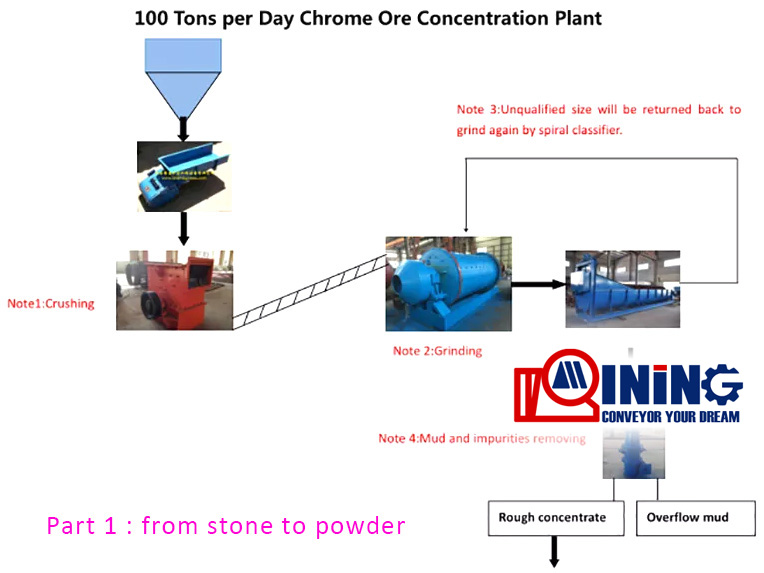

Main equipment flow of active lime rotary kiln

Calcination mechanism of active lime

Theoretical decomposition temperature: 870~920℃

Theoretical unit consumption: about 1200 kcal/kg

Activity guarantee basis: raw materials, preheating decomposition, calcination temperature and time, kiln performance

Limestone cannot be directly calcined into lime at 900~1000℃.

Preheating stage: It is gradually transformed from low temperature to high temperature (200~900℃), and the decomposition rate reaches 25%.

Firing stage: in the rotary kiln from the beginning of contact with the radiant heat transfer of the flame, to before passing through the entire flame radiation area. The belt is about 15 meters long.

Cooling stage: The material moves under the burner.

Vertical preheater:

Negative pressure, convective heat transfer, using the waste heat of exhaust gas, the material stays for about 120 minutes.

Rotary kiln :

Negative pressure, radiation heat transfer, rotary heat transfer enhancement, fast burning, the material stays for about 30-40 minutes.

Vertical cooler:

Positive pressure, convection heat transfer, mechanical ventilation, quenching, the material stays for about 30 minutes.

Introduction of horizontal lime rotary kiln

Lime rotary kiln is a new type of special rotary kiln for active lime developed on the basis of absorbing and learning from the same type of rotary kiln at home and abroad, aiming at the calcining characteristics of limestone.

Lining material

In the firing zone: magnesia-aluminum spar (refractory and alkali-resistant);

Liner of lime rotary kiln

Feeding end: high alumina and clay lining bricks, castables (refractory and wear-resistant);

Discharge (exit) place: corundum or high alumina refractory material, castable (refractory, wear-resistant and thermal shock resistance).

lime rotary kiln working principle and application

Working principle: negative pressure, countercurrent.

Gas flow rate: moderate in size.

Application of horizontal lime rotary kiln

It is suitable for calcined limestone in metallurgy, chemical and building materials industries.

Characteristics of horizontal lime rotary kiln

Lime rotary kiln features:

The material is tumbling, heated evenly, with high activity and high purity.

The operation process is easy to control and the production volume is large.

High utilization rate of raw materials, complete calcination, uniform quality, good quality,

Long machine life

Parameter of the Lime rotary kiln

| Capacity (tpd) | 150 | 200 | 250 | 300 | 350 | 400 | 500 | 600 | 800 | 1000 | 1200 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Vertical preheater | YRQ04 | YRQ06 | YRQ06 | YRQ08 | YRQ08 | YRQ10 | YRQ12 | YRQ12 | YRQ14 | YRQ18 | YRQ20 |

| Rotary kiln | φ2.5×40m | φ2.8×43m | φ3.0×48m | φ3.2×50m | φ3.3×52m | φ3.6×55m | φ3.8×58m | φ4.0×60m | φ4.3×65m | φ4.9×70m | φ5.1×72m |

| Vertical cooler | LSF36 | LSF44 | LSF56 | LSF80 | LSF112 | ||||||

| Calcination TEMP( ℃ ) | 1100±50 | ||||||||||

| Energy consumption(kCal/kg) | 1200±100 | ≤1150 | ≤1100 | ||||||||

| Power consumption | 40±5 | ||||||||||

| Feeding size ( mm ) | 10~20/20~40 | ||||||||||

| Emission CONC (mg/Nm3) | ≤10 | ||||||||||

| Working days per year | ≥340 | ||||||||||

| Operators | 2~3 | ||||||||||

Burner and Fuel

Fuel:

At the same time, pulverized coal, coke oven gas, blue charcoal furnace gas, converter gas, blast furnace gas, calcium carbide furnace gas, natural gas, diesel oil, heavy oil, liquefied petroleum gas, and biomass fuel can be widely used as raw fuel materials.

Burner:

The burner, commonly known as the burner, largely determines the operating state of the kiln.

Influencing factors of flame shape: burner structure, fuel properties, kiln length, inner diameter, air configuration, ventilation state, etc.

Fuel Supply System: Practical and Economical

Primary fan: ideal flame shape

Ignition system: artificial ignition, automatic ignition

Combustion Control System: Interlock

Smoke machines

Status: Known as the heart, very important.

Function: discharge exhaust gas, form a negative pressure state, guide heat transfer and exchange, and maintain stability.

Dust collector

Commonly used dust removal equipment includes electrostatic precipitator, bag filter, cyclone, dust chamber, inertial precipitator, water precipitator, etc.