XJM coal flotation machine

XJM coal flotation machine washing tank - China Henanmining

Coal flotation machine video

Application of Coal flotation machine

It is suitable for flotation of various floatable slimes with particle size below 0.5mm in various bituminous coals and anthracite; Suitable for use in large, medium, and small coal washing plants.

Features of Coal flotation machine

1.It is a self priming air mechanical stirring type, suitable for flotation of coal slime with a particle size of<0.5mm;

2.High uniformity of inflation, good flotation selectivity, and reliable operation;

3.Low energy consumption and at best high energy consumption among similar products;

4.At present, more than a thousand units have been promoted, making it an ideal replacement product for flotation machines.

Parameter of the XJM coal flotation machine

| Model | XJM-S4 | XJM-S6 | XJM-S8 | XJM-S12 | XJM-S14 | XJM-S16 | XJM-S20 | XJM-S24 | XJM-S28 | XJM-S36 | XJM-S45 |

| Single volume(m³) | 4 | 6 | 8 | 12 | 14 | 16 | 20 | 24 | 28 | 36 | 45 |

| Unit capacity(t/m³·h) | 0.6~1 | 0.6~1 | 0.6~1 | 0.6~1 | 0.6~1 | 0.6~1 | 0.6~1 | 0.6~1 | 0.6~1 | 0.6~1 | 0.6~1 |

| Unit slurry capacity (m³/ m³·h) | 6~10 | 6~10 | 6~10 | 6~10 | 6~10 | 6~10 | 6~10 | 6~10 | 6~10 | 6~10 | 6~10 |

| Inflation rate(m³/㎡·min) | 0.6~1.2 | ||||||||||

| Mixing power(kw) | 15 | 18.5 | 22 | 30 | 30 | 37 | 45 | 55 | 55 | 75 | 75 |

| Scraping power(kw) | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 2.2 | 2.2 | 4 | 4 | 4 | 4 |

| Length - 3 tanks(mm) | 6785 | 7685 | 8200 | 9494 | 10200 | 10970 | 12260 | 12564 | 13313 | 14515 | 16545 |

| Length - 4 tanks(mm) | 8690 | 9890 | 10555 | 12254 | 13205 | 14175 | 15715 | 16272 | 17271 | 18870 | 21555 |

| Length - 5 tanks(mm) | 10595 | 12095 | 12910 | 15014 | 16210 | 17380 | 18170 | 19980 | 21229 | 23225 | 26565 |

| Width(mm) | 2150 | 2150 | 2750 | 3120 | 3270 | 3450 | 3700 | 3950 | 4200 | 4600 | 4870 |

| Height(mm) | 2758 | 2758 | 2956 | 3250 | 3310 | 3433 | 3503 | 3566 | 3607 | 4728 | 4805 |

XJM coal flotation machine

Scraper structure of xjm flotation machine

mixing structure of xjm flotation machine

spare parts of xjm coal flotation machine

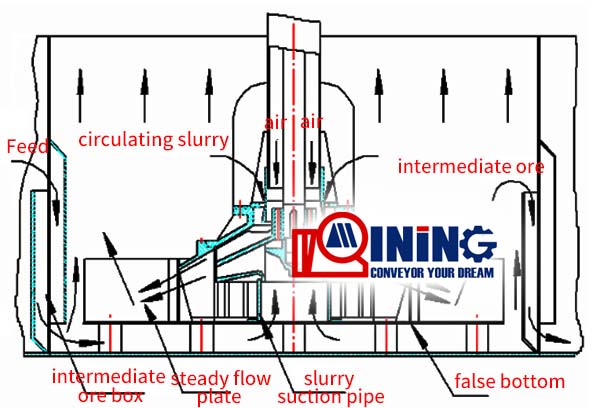

Working principle of coal flotation machine

The pretreated slurry is fed to the false bottom of the first chamber of the flotation machine, and the negative pressure formed by the rotation of the impeller in the wheel chamber causes the slurry under the false bottom and in the tank to enter the mixing zone through the lower and upper suction ports of the impeller, respectively.

This also allows air to enter the mixing zone along the air guide sleeve, where the slurry, air, and reagents are mixed. Under the centrifugal force of the impeller, the mixed slurry enters the mineralization area, and the inhaled air is sheared to form bubbles and crushed.

It contacts with the coal particles to form mineralization bubbles. Under the action of the stator and turbulence plate, it is evenly distributed on the section of the tank body, and moves upward into the separation area to form a foam layer that is enriched and discharged by the foam scraping mechanism to form a cleaned coal foam.

The unmineralized coal particles on the false bottom will be sucked into the impeller through the circulation hole and upper suction port, and then mixed, mineralized, and separated again. The portion of the ore slurry that has not been mineralized in a timely manner inside the tank enters the false bottom of the second chamber through the middle ore box buried in the slurry, just like the entire process completed in the first chamber before entering the third chamber.

This cycle continues, and the ore slurry passes through the last chamber and then enters the tailings tank to discharge the tailings.

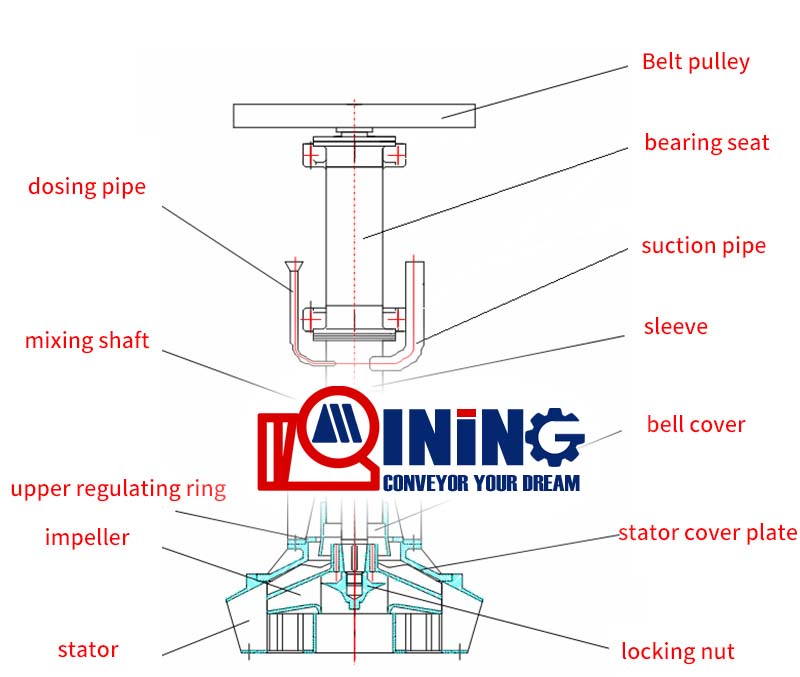

Mixing structure

XJM flotation machine structure consists of Belt pull, bearing seat, suction pipe, sleep, bell cover, stat cover plate, locking nut, stat, importer, upper regulating ring, mixing shaft, Dosing pipe etc.