Clothes shredding machine shredder

Clothes shredding machine, factory price textile crusher shredder China

Clothes shredding machine Application

It is suitable for crushing all kinds of clothes:

waste fabrics, machine head materials, all kinds of waste scraps, waste leather, cowhide, fibers, textile , fabric, old shoes, carpets, quilts and all kinds of waste life, office Supplies etc. The output size can be adjusted according to user requirements.

Clothes shredding machine Introduction

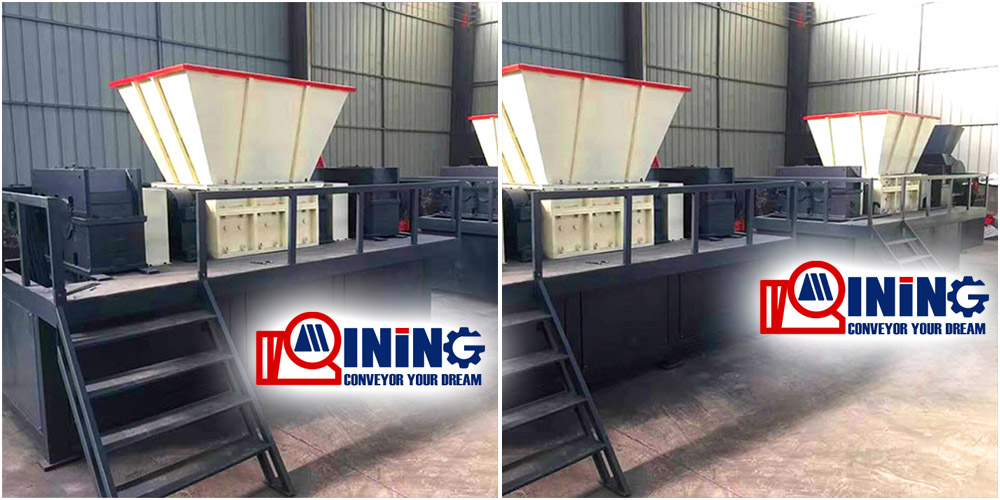

Clothes shredder machine includes Double shaft shredder and Single shaft shredder. The double-shaft shredder adopts double-shaft independent drive, so that the material will be pressed correspondingly during production to achieve the automatic feeding function. The unique cutter shaft structure and four-corner rotary cutter can be used in the production process of low speed and high torque. , There will be no winding shaft or jamming of the equipment, thus improving the production efficiency. The equipment is suitable for the crushing of various materials with high toughness and viscosity.

For more introduction click : Shredder operation manual: How to operate shredder machine daily

Clothes shredding machine video

Click sheredder videos column for more videos.

Clothes shredder machine for sale

Clothes shredder machine for sale

Clothes shredder machine for sale

Clothes shredder machine for sale

Parameter of the Clothes shredding machine shredder

| 1.Capacity: As per material; 2. Customization support ; 3.Protection System: PLC,overload protection | ||||||

| Model | Power | Shaft diameter(mm) | Blade diameter(mm) | Blade number | Rotating speed | Dimension(mm) |

|---|---|---|---|---|---|---|

| S-300 | 3-5.5KW | 80 | 180-250 | 20-30 | 12-16 | 800*480*1300 |

| S-400 | 3-7.5KW | 90 | 180-250 | 20-30 | 12-16 | 850*500*1300 |

| S-500 | 4-11KW | 100 | 200-300 | 20-30 | 12-16 | 850*500*1300 |

| S-600 | 15-22KW | 100 | 250-350 | 20-30 | 12-16 | 1200*600*1550 |

| 2S-400 | 4-7.5KW*2 | 80 | 180-250 | 20-40 | 10-15 | 1200*600*1550 |

| 2S-500 | 5.5-11KW*2 | 90 | 200-300 | 25-40 | 10-15 | 1550*660*1800 |

| 2S-600 | 11-22KW*2 | 130 | 250-350 | 20-45 | 10-15 | 3200*1500*2500 |

| 2S-800 | 22-37KW*2 | 160 | 300-400 | 16-40 | 10-15 | 3600*1560*2600 |

| 2S-1000 | 30-45KW*2 | 180 | 400-500 | 25-50 | 8-14 | 3800*1650*2600 |

| 2S-1200 | 30-75KW*2 | 180 | 400-500 | 20-60 | 8-14 | 4200*1750*2700 |

| 2S-1300 | 30-90KW*2 | 200 | 400-500 | 26-65 | 8-14 | 4300*1800*2800 |

| 2S-1400 | 45-90KW*2 | 220 | 450-550 | 20-46 | 13-16 | 4600*2200*2800 |

| 2S-1500 | 45-110KW*2 | 240 | 450-550 | 20-50 | 13-16 | 4600*2200*2800 |

Clothes shredder machine Advantages:

1.The blade is made of cold-worked die steel, which has good strength, high toughness and high cutting performance. The blade has four cutting edges, which can be rotated 90° after wear and continue to be used.

2.The external bearing design is waterproof and dustproof, extending the service life of the bearing.

3.Forced hydraulic feeding, stable and adjustable speed, large and uniform propulsion.

4.Hard tooth surface reducer, high transmission efficiency, strong carrying capacity and low noise.