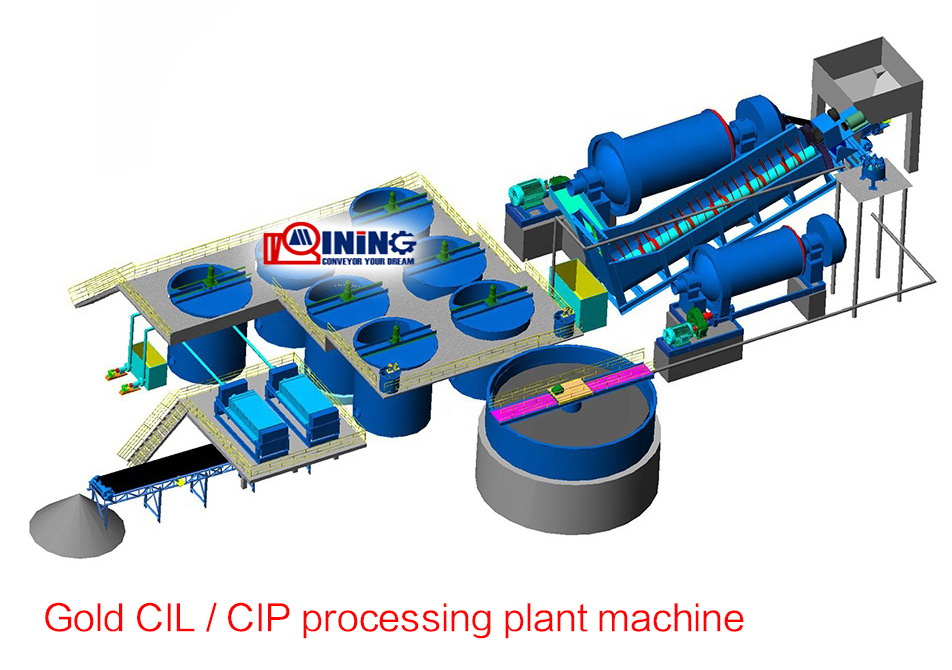

Gold ore processing plant CIL CIP leaching line

Gold ore processing plant CIL CIP leaching line machine

Equipment list :( Take as a reference)

| Machine Name | Model | QTY |

|---|---|---|

| Fine Jaw Crusher | PEX150x750 | 1 |

| Vibrating Screen | SZZ900x1800 | 1 |

| Swaying Feeder | BK400x400 | 1 |

| Gold Ball Mill | MQG1500x3500 | 1 |

| Spiral Classifier | FLG1200 | 1 |

| Cyclone | FX-125-II | 2 |

| Slurry Pump | 50-ZBD-50 | 2 |

| Submerged Pump | 15-YP-25 | 1 |

| Mining Thickener | NZS-10 | 1 |

| agitation tank | BJW-1000x1000 | 1 |

| Liner Vibrating Screen | DZS0415 | 1 |

| Leaching Tank | SJ3.5x4.0 | 7 |

| Roots Fan | L42LD | 2 |

| Carbon Separation screen | SY300 | 6 |

| agitation tank | BJW-1000 | 1 |

| Air lifter | KT-100 | 1 |

| Submerged Pump | 15-YP-25 | 2 |

Gold Ore CIL / CIP Plant

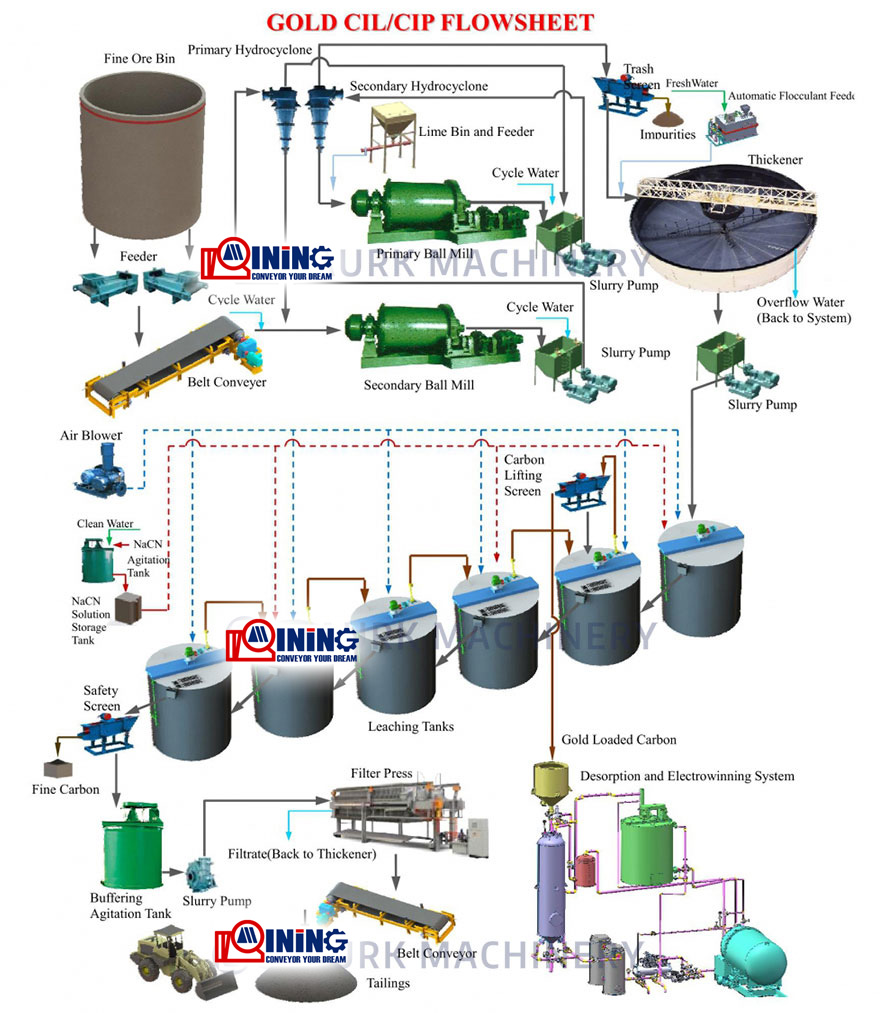

CIL / CIP is gold cyanide extraction process.Gold Ore CIL / CIP Plant uses Jaw Crusher, Ball mill, Spiral Classifier, Carbon Leaching tanks, Centrifuged Concentrator, shaking tables. Enabling a 98% gold extraction rate.

4 STEPS:

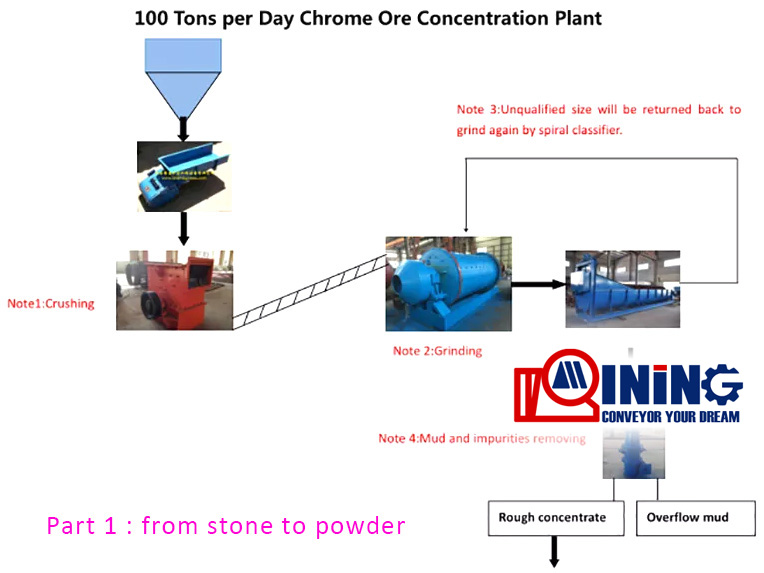

1 : Crushed material will be ground by ball mill and classified into 85% of 200 mesh,

2 : Fine powder will get into thickener , after concentration, will add chemical and carbon in the tank,

3 : After leaching and absorption , get gold loaded carbon.

4 : we can use electrolysis equipent and furnace to get gold bar.

In this CIL process, you can get gold on the carpet, inside of gold concentrator,shaking table, and electrolysis system, The revovery rate is above 98%

Parameter of the Gold ore processing plant CIL CIP leaching line